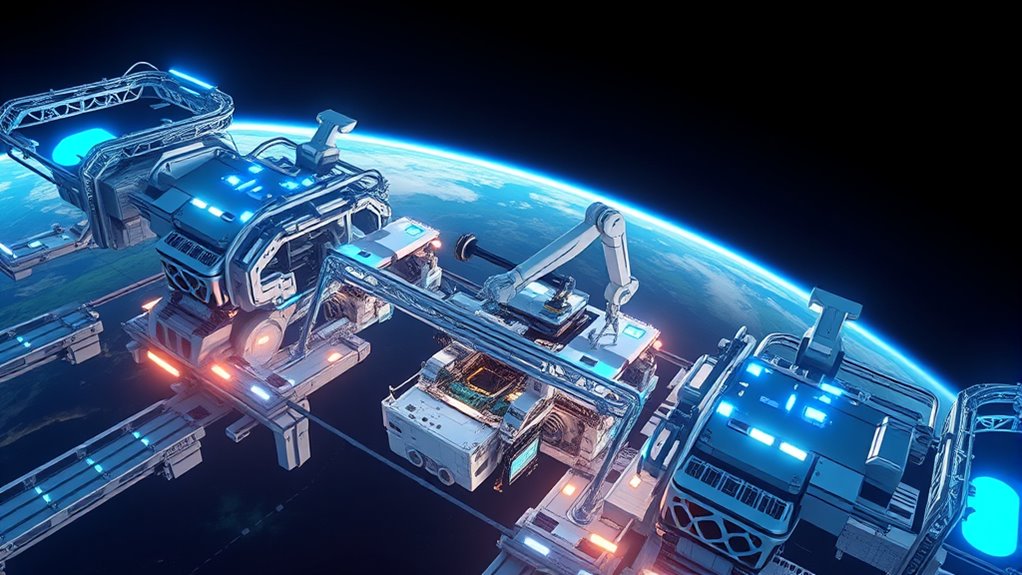

Orbital factories in zero gravity let you produce perfect, high-quality products that can’t be made on Earth. Using advanced robotics and precise control techniques, they create complex structures with minimal waste and contamination. Industries like space farming, mining, and electronics benefit from these factories, which also reduce environmental impact. Though challenges exist, innovations and collaborations are revealing the full potential of space manufacturing. Discover how this industry is shaping the future and what’s next.

Key Takeaways

- Zero-G environments enable the production of perfectly uniform, high-quality products essential for space tourism and medical applications.

- Orbital factories utilize advanced robotics and automation for precise, scalable manufacturing in microgravity.

- Manufacturing in space reduces contamination, waste, and allows complex structures to be created in a single step.

- Zero-G conditions facilitate the creation of complex, pure materials for electronics, pharmaceuticals, and high-precision components.

- Space-based manufacturing supports sustainable resource use, reduces Earth’s environmental impact, and opens new markets beyond Earth.

The Advantages of Manufacturing in Zero Gravity

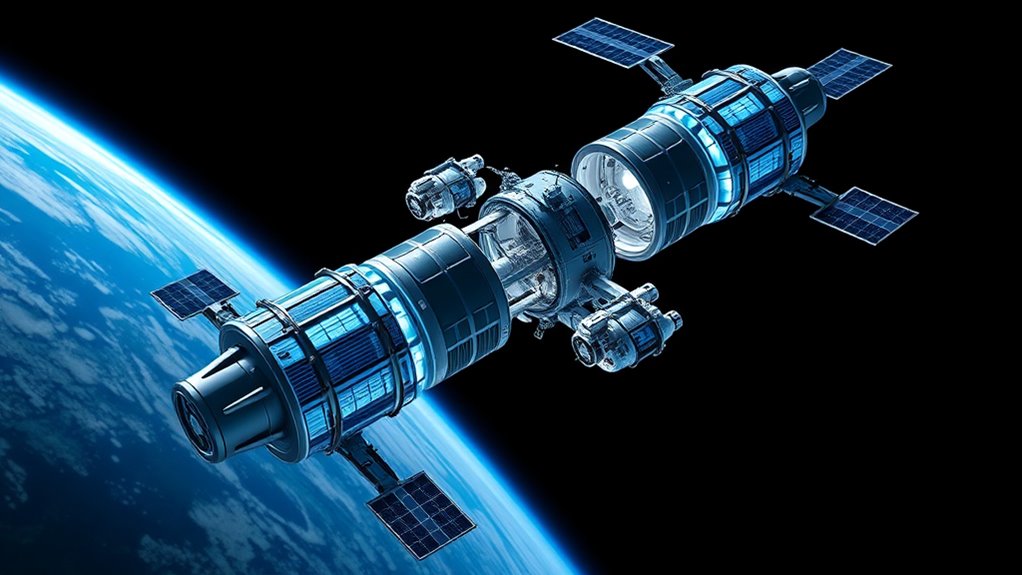

Manufacturing in zero gravity offers several compelling advantages that are difficult to achieve on Earth. Without gravity, you can produce perfectly uniform products, essential for advanced space tourism equipment and sensitive medical devices. Zero-G also allows for the creation of complex structures in a single step, reducing manufacturing time and costs. This environment benefits extraterrestrial mining operations by enabling the extraction and processing of raw materials directly in space, minimizing the need to transport resources back to Earth. Additionally, manufacturing in orbit reduces contamination and allows for the development of innovative materials that would degrade under Earth’s gravity. Studying space manufacturing techniques can further enhance our understanding of these processes. As space tourism grows, these orbital factories will guarantee high-quality, reliable products, opening new possibilities for human activity beyond our planet.

Key Technologies Enabling Orbital Production

You need reliable microgravity manufacturing techniques, robotic assembly systems, and advanced material handling to make orbital production feasible. These technologies work together to enable precise, efficient construction and processing in space. Understanding how they integrate is key to unblocking the full potential of orbital factories. Celebrating fatherhood serves as an inspiration for nurturing growth and development in various aspects of life, including technological advancements like orbital factories.

Microgravity Manufacturing Techniques

Have you ever wondered how microgravity releases new possibilities for production? In space, the absence of gravity allows for innovative manufacturing techniques that improve product quality. Microgravity enables precise control over material behavior, making processes like space farming more efficient by reducing soil compaction and optimizing plant growth. It also benefits extraterrestrial mining, where zero-G conditions facilitate the extraction and processing of raw materials with fewer impurities. Techniques like fluid dynamics manipulation and specialized manufacturing chambers lead to higher purity products and stronger materials. These methods reduce waste and improve precision, ensuring better outcomes than traditional Earth-based processes. Additionally, the impact of contrast ratio on image quality highlights the importance of detailed control in manufacturing environments. Overall, microgravity manufacturing techniques open a new frontier for producing flawless products, harnessing the unique environment of space to revolutionize industries on and off Earth.

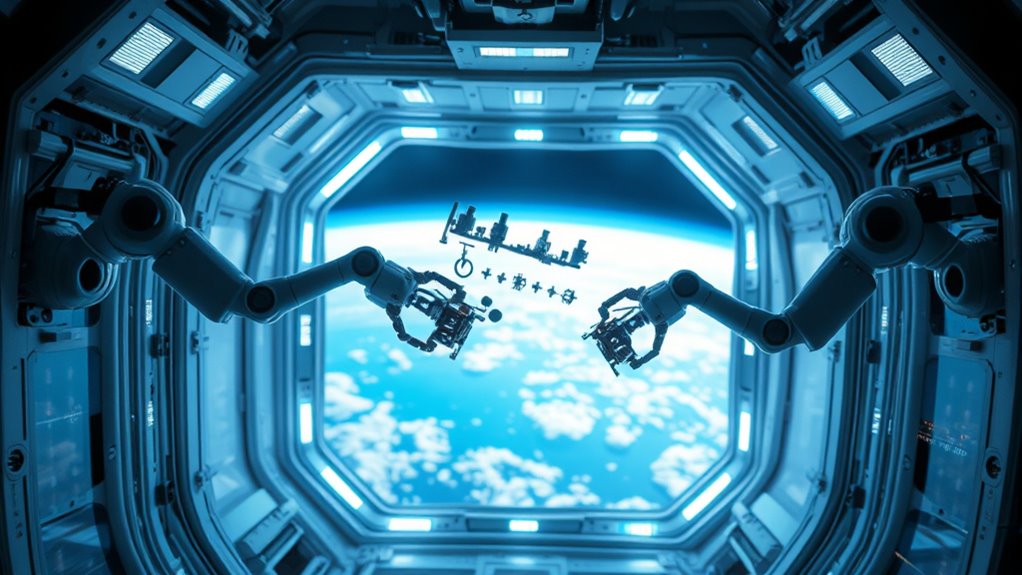

Robotic Assembly Systems

Robotic assembly systems are transforming how products are constructed in orbit, leveraging advanced automation to build complex structures in the challenging environment of space. These systems enable efficient, precise assembly of components for space habitats, reducing the need for human extravehicular activity. With robotic arms and intelligent algorithms, you can streamline orbital logistics, ensuring that parts are delivered and assembled seamlessly. Robotic systems handle delicate tasks like installing sensitive equipment or forming structural frameworks, increasing safety and reducing errors. They operate continuously, optimizing productivity and turnaround times for manufacturing in zero-G. By integrating sensors and adaptive controls, you gain real-time feedback for perfect alignment and fit. Additionally, incorporating balancing poses into robotic algorithms can enhance stability during complex assembly tasks. Ultimately, robotic assembly systems make orbital production more reliable, flexible, and scalable, paving the way for sustainable space-based manufacturing.

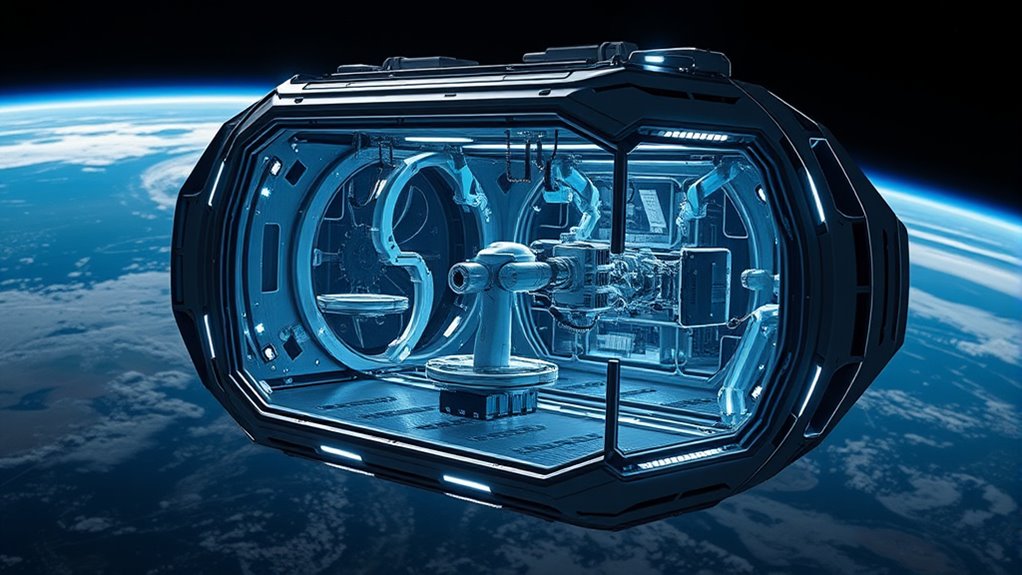

Advanced Material Handling

How are advanced material handling technologies revolutionizing orbital production? They streamline orbital logistics, allowing you to move materials efficiently in zero-G environments. These systems use robotics and smart automation to handle delicate components precisely, reducing the risk of errors. Managing space debris is critical, as debris can obstruct or damage equipment, so advanced handling tools are designed to avoid collisions. By integrating sensors and AI, you can track and manipulate items in real-time, ensuring safe and accurate transfers. This minimizes delays caused by debris or misplacement, boosting productivity. Additionally, these technologies support sustainable manufacturing practices by reducing waste and optimizing resource use. As a result, orbital factories become more autonomous, reliable, and capable of producing perfect products, even amid the challenges of space debris and complex logistics. This technology is key to sustainable, high-quality manufacturing in orbit.

Industries Poised to Benefit From Space-Based Factories

As space-based factories become a reality, several industries stand to gain significant advantages. Space farming could revolutionize food production, providing fresh crops in orbit and reducing reliance on Earth supplies. This opens possibilities for long-term missions and lunar or Martian settlements. Extraterrestrial mining stands to benefit as well, enabling the extraction of rare minerals and metals from asteroids and planets with minimal Earth’s environmental impact. Manufacturing in zero-G allows for the creation of purer, higher-quality materials, enhancing product performance across sectors. Additionally, industries like pharmaceuticals and electronics can produce more precise, flawless products without terrestrial constraints. Overall, space-based factories promise to transform industries by offering access to unique resources and manufacturing environments, paving the way for a new era of innovation and efficiency beyond our planet.

Overcoming Challenges in Space Manufacturing

You’ll need to understand how microgravity can boost manufacturing processes, but it also presents unique technical and logistical challenges. Overcoming these hurdles requires innovative solutions to guarantee reliable operations in space. Addressing these issues is key to opening the full potential of orbital factories. Implementing specialized tuning techniques can optimize machinery performance and adapt to the space environment.

Microgravity’s Manufacturing Benefits

Microgravity offers unique advantages for manufacturing that are difficult or impossible to achieve on Earth. In zero gravity, you can conduct space mining more efficiently, as materials separate without gravity interference, resulting in purer resources. This environment also enables zero gravity research, where you can produce perfect crystals, advanced alloys, and high-quality pharmaceuticals free from sedimentation or contamination. This core personality traits environment also allows for precise control over chemical reactions, leading to superior material properties. These benefits open new possibilities for creating products with unmatched quality and consistency. By harnessing microgravity, you can overcome traditional manufacturing limitations, making space the ideal laboratory for innovation and discovery. This environment transforms how you approach manufacturing challenges in the quest for perfect products.

Technical and Logistical Hurdles

Overcoming the technical and logistical hurdles of space manufacturing requires addressing complex engineering challenges and resource limitations. One major obstacle is space debris, which risks damaging equipment and increasing safety concerns. Managing and avoiding debris is essential to ensure safe operations and protect valuable assets. Additionally, high launch costs pose a significant barrier to establishing and expanding orbital factories. You must develop cost-effective methods to transport materials and equipment to space while minimizing payload weight. Logistical planning also involves ensuring reliable power sources, maintaining equipment in zero-G, and creating systems that can operate autonomously. The development of space-specific manufacturing techniques is crucial to adapt to the unique conditions of the space environment. Overcoming these hurdles demands innovative engineering, careful resource management, and international cooperation to make space manufacturing feasible and sustainable.

Cost Considerations and Economic Impacts

Cost considerations and economic impacts play a essential role in determining the feasibility of orbital factories. Achieving cost efficiency is fundamental because launching materials and maintaining operations in orbit require significant investment. You’ll need to weigh the high initial expenses against long-term savings from faster production cycles and higher-quality outputs. While establishing orbital manufacturing may seem costly upfront, it can promote economic growth by creating new markets and job opportunities in space industries. Additionally, the ability to produce perfect products in zero-G reduces waste and rework costs, improving overall profitability. Furthermore, advancements in space manufacturing technology are critical to reducing operational costs and increasing scalability of orbital factories. However, scaling these operations depends on balancing these costs with the potential economic benefits. Careful planning and technological advancements will be indispensable to making orbital factories a financially viable and impactful venture.

The Role of Robotics and Automation in Orbital Factories

Robotics and automation are transforming orbital factories by enabling precise remote operations that reduce errors and improve safety. Autonomous quality control systems continuously monitor and adjust processes to guarantee top standards without human intervention. Adaptive manufacturing systems respond dynamically to changing conditions, increasing efficiency and flexibility in space-based production. Additionally, incorporating Vetted technologies ensures that all processes adhere to the highest standards of reliability and safety.

Precision Remote Operations

Have you ever wondered how orbital factories achieve such incredible precision? It all comes down to advanced robotics and automation working through precision remote operations. These systems rely heavily on sophisticated spacecraft design, enabling tools and manipulators to perform delicate tasks with accuracy in zero-G. You control operations remotely, steering complex orbital logistics to position components precisely. Real-time data feeds and high-resolution sensors guide your actions, ensuring flawless assembly and manufacturing. Automated systems handle repetitive tasks, while human operators oversee the process from Earth, making adjustments as needed. This seamless integration of robotics and remote control minimizes errors, maximizes efficiency, and guarantees the production of perfect products in space. Precision remote operations are the backbone of reliable, high-quality manufacturing beyond Earth’s atmosphere.

Autonomous Quality Control

Building on the precision remote operations that keep orbital factories running smoothly, autonomous quality control systems play a vital role in maintaining product standards. These systems leverage advanced robotics and sensors to detect flaws, contamination, or deviations instantly. With space debris and complex orbital logistics, manual inspections are impractical; automation ensures continuous oversight.

Here’s how autonomous quality control keeps production on track:

- Real-time Monitoring: Sensors detect defects immediately, reducing waste.

- Robotic Inspections: Drones and robotic arms perform non-invasive checks, even in cluttered or debris-prone environments.

- Data Integration: AI analyzes inspection data to optimize manufacturing processes and preempt issues.

This automation guarantees product integrity while minimizing risks posed by space debris and logistical challenges.

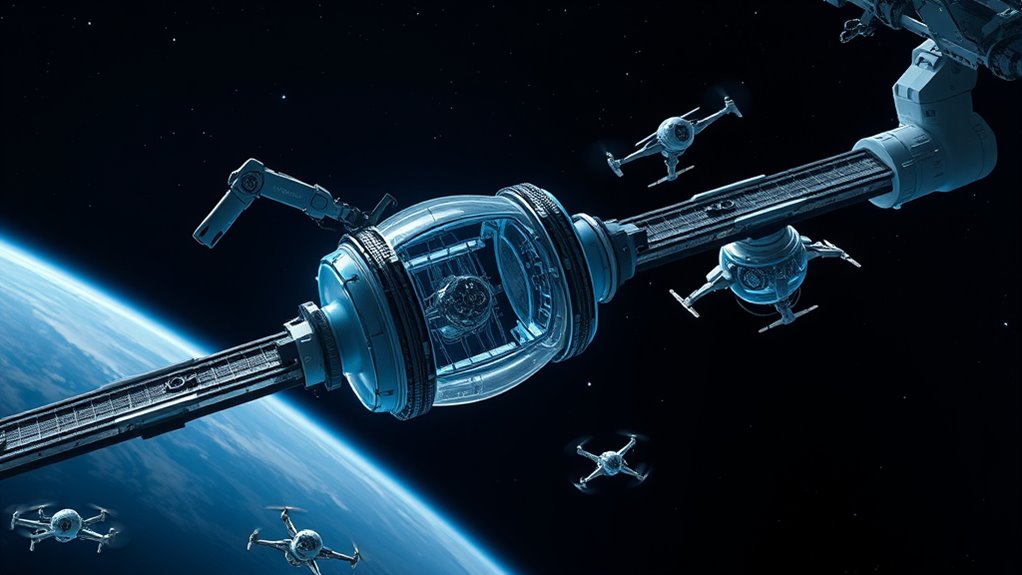

Adaptive Manufacturing Systems

As orbital factories advance, adaptive manufacturing systems harness the power of robotics and automation to respond dynamically to changing conditions. In zero-g environments, these systems excel in tasks like space farming, adjusting nutrient delivery and growth conditions in real-time to maximize yields. They also support zero-g art installations, precisely manipulating materials to create intricate designs without human intervention. Robotics can reconfigure production lines instantly, enabling the factory to switch between manufacturing perfect products and experimental projects. This flexibility guarantees efficiency and innovation in orbit. By continuously learning and adapting, these systems maintain ideal operations despite the unique challenges of zero gravity, making orbital factories more versatile, resilient, and capable of producing a diverse range of high-quality outputs.

Environmental Benefits of Space Manufacturing

Space manufacturing offers significant environmental benefits by reducing the strain on Earth’s resources and minimizing pollution. By shifting production off-planet, you can cut down on resource extraction and waste. Additionally, space factories help address space debris concerns by enabling in-orbit recycling and manufacturing, reducing clutter risks. Here are three key advantages:

- Lower Earth Pollution: Less industrial activity on Earth means fewer emissions and pollutants.

- Efficient Launch Logistics: Producing in space cuts the need for frequent launches, decreasing fuel consumption and associated emissions.

- Reduced Resource Extraction: Manufacturing in orbit minimizes the need for mining and processing on Earth, preserving ecosystems.

Future Developments and Innovations in Zero-G Production

Advancements in zero-gravity manufacturing are opening new possibilities for producing high-quality materials and complex components that are difficult or impossible to make on Earth. As space tourism grows, demand for durable, lightweight products increases, driving innovation in orbital factories. These developments enable the production of superior materials for luxury space accommodations and equipment. Additionally, zero-G manufacturing boosts extraterrestrial mining efforts by allowing the creation of specialized tools and processing units directly in space, reducing reliance on Earth-based supply chains. Future innovations may include automated factories that adapt to different manufacturing needs, improving efficiency and safety. These advancements will make space-based production more cost-effective, supporting broader space exploration, tourism, and resource exploitation, ultimately transforming how we create and utilize products beyond our planet.

Collaborations Between Public Agencies and Private Sector

Public agencies and private companies are increasingly joining forces to accelerate the development of orbital factories and zero-G manufacturing technologies. These collaborations are driven by evolving space policies that encourage public-private partnerships and foster innovation. By working together, they can leverage each other’s strengths to overcome technical and regulatory challenges. Here are three ways these partnerships are making a difference:

- Sharing expertise and resources to optimize manufacturing processes in space.

- Forming international partnerships that expand market access and establish global standards.

- Aligning space policy to streamline regulations and promote sustainable, long-term orbital manufacturing.

This synergy accelerates innovation, making zero-G manufacturing more efficient and accessible, paving the way for a new era of global production beyond Earth.

Envisioning the Next Era of Global Manufacturing

As collaborations between public agencies and private companies reshape orbital manufacturing, a new vision for global production emerges—one that stretches beyond current capabilities. Imagine space habitats serving as advanced manufacturing hubs, where zero-G conditions enable perfect products. This shift will redefine how we think about supply chains, with orbital logistics becoming essential for seamless transportation of raw materials and finished goods. You’ll see factories in space that produce high-value items, from pharmaceuticals to electronics, reducing Earth’s environmental impact. The next era of manufacturing will leverage these orbital platforms for rapid, cost-effective, and sustainable production. This vision not only enhances global innovation but also creates new opportunities for industries to collaborate across borders, making space an integral part of our manufacturing future.

Frequently Asked Questions

How Will Space Manufacturing Influence Earth’s Resource Depletion?

Space manufacturing could substantially reduce Earth’s resource depletion by allowing you to produce goods using fewer raw materials and less energy. This shift helps conserve resources and minimizes environmental impact, as manufacturing in space avoids land disruption and pollution. By moving some production off-planet, you can lessen the strain on Earth’s ecosystems, promoting sustainability and ensuring resources remain available for future generations.

What Legal and Regulatory Issues Affect Orbital Factories?

You need to contemplate how space law and regulatory challenges impact orbital factories. As space manufacturing grows, legal issues like property rights, environmental protections, and international treaties become critical. Maneuvering these laws requires you to stay compliant with regulations set by agencies like the UN and national authorities. Addressing these legal hurdles ensures your operations are lawful, sustainable, and avoid conflicts, paving the way for successful space-based manufacturing ventures.

How Can Space Manufacturing Ensure Product Quality and Safety?

To guarantee product quality and safety, you should focus on maintaining high material purity and manufacturing precision. In space, the absence of gravity can impact material properties, so rigorous quality controls are essential. Implement strict testing protocols, precise manufacturing processes, and continuous monitoring to detect any deviations. These steps help you produce reliable, safe products, leveraging the unique environment of space to improve overall quality and safety standards.

What Are the Long-Term Sustainability Prospects for Space-Based Industries?

You might wonder about the long-term sustainability of space-based industries. If you address space debris effectively and utilize lunar resources wisely, you can reduce environmental impact and dependence on Earth’s finite supplies. By implementing responsible practices and innovations, you guarantee these industries remain viable and beneficial for decades. This proactive approach helps balance growth with preservation, securing a sustainable future for space exploration and commercialization.

How Will Orbital Factories Impact Global Supply Chains and Economies?

Many believe orbital factories will revolutionize global supply chains and economies, and there’s truth to that. You’ll see a shift as space infrastructure supports faster, more efficient manufacturing, reducing costs and opening new markets. The space workforce will grow, creating jobs and innovation. This change could lead to more resilient supply chains, less dependency on Earth’s resources, and a boost to global economies as space-based industries become integral.

Conclusion

As you look to the future, remember that space manufacturing offers innovation, efficiency, and sustainability. You’ll see industries transform, technologies evolve, and economies grow. You’ll harness zero gravity for perfection, overcome challenges with creativity, and collaborate across sectors for progress. You’ll embrace the endless possibilities of orbital factories, shaping a new era in global manufacturing—an era where innovation, opportunity, and sustainability work hand in hand, propelling you toward a brighter, limitless future.