Generative algorithms are transforming car design by enabling you to create vehicles that are lighter, stronger, and more innovative. These advanced computational tools optimize structures, materials, and aesthetics, helping manufacturers develop unique, efficient, and sustainable models faster than ever. By automating complex design iterations, they allow you to explore new shapes, materials, and configurations. If you explore further, you’ll discover how these algorithms are shaping the future of automotive engineering and manufacturing.

Key Takeaways

- Generative algorithms optimize vehicle shapes for enhanced aerodynamics, safety, and material efficiency through complex, organic geometries.

- They enable rapid iteration of design concepts, fostering innovation and customization in vehicle aesthetics and interior layouts.

- Algorithm-driven processes reduce manufacturing costs by optimizing material use, weight reduction, and structural performance.

- AI-powered generative design supports sustainability by incorporating recycled materials and creating lightweight, durable components.

- Case studies demonstrate improvements in energy efficiency, safety features, and autonomous system integration through algorithmic engineering.

The Evolution of Automotive Design Techniques

The evolution of automotive design techniques has been driven by technological advancements and changing consumer preferences. You notice that modern cars no longer just focus on function—they embody aesthetic symbolism that communicates style and sophistication. This shift helps strengthen brand identity, making vehicles instantly recognizable and emotionally appealing. Designers now leverage new tools to craft shapes that evoke feelings, convey luxury, or suggest innovation. Over time, streamlined forms, bold grilles, and distinctive lighting have become signature elements that set brands apart. You see how aesthetic choices reflect a company’s values and target audience, transforming cars from mere transportation into symbols of identity. As technology advances, these design techniques continue to evolve, blending art with engineering to create vehicles that resonate deeply with consumers. Additionally, the integration of generative design algorithms allows for more innovative and precise shapes, pushing the boundaries of traditional automotive aesthetics.

How Generative Algorithms Transform Vehicle Development

Generative algorithms are revolutionizing vehicle development by speeding up design innovation and enabling faster iteration. They help you optimize material use, reducing weight without sacrificing strength, which improves performance and efficiency. Additionally, these algorithms let you customize vehicle aesthetics, offering unique, tailored designs that meet specific preferences.

Accelerating Design Innovation

As automotive designers embrace cutting-edge algorithms, they can now rapidly explore a vast array of innovative vehicle configurations. This acceleration allows for more creative freedom, especially in areas like user interface and interior lighting. You can test dynamic lighting schemes that adapt to driver preferences or mood, optimizing interior ambiance with minimal effort. Generative algorithms suggest unique interior layouts and interactive controls, streamlining the design process. By automating complex iterations, you save time and focus on refining user experience. With this technology, you’re empowered to push boundaries, creating interiors that are both functional and visually striking. Additionally, understanding relationship dynamics within design teams can enhance collaboration and innovation. Ultimately, these innovations lead to vehicles that better meet driver needs and elevate overall driving experiences, transforming how you approach automotive design.

Optimizing Material Use

By harnessing generative algorithms, automotive developers can substantially improve material efficiency throughout the vehicle design process. These algorithms identify best structures that minimize material waste while maintaining strength and safety. You can incorporate recycled materials, reducing environmental impact and costs. Lightweight construction becomes more achievable, enhancing fuel efficiency and performance. Generative design enables the creation of complex, organic shapes that use less material without sacrificing durability. You might also explore hybrid approaches, blending recycled materials with traditional components for sustainability. This process ensures smarter material use, leading to more eco-friendly, cost-effective vehicles. As a result, manufacturers can develop lighter, more efficient cars that meet sustainability goals without compromising quality or safety. Additionally, material optimization techniques play a crucial role in maximizing resource efficiency and reducing waste during manufacturing.

Customizing Vehicle Aesthetics

Advancements in generative algorithms are revolutionizing how vehicle aesthetics are designed, allowing for highly customized and innovative appearances. You can now tailor interior customization to match your personal style, selecting unique materials, layouts, and finishes that reflect your preferences. The algorithms generate a wide range of options, enabling you to experiment with different design elements effortlessly. Color palette selection becomes more dynamic, as generative tools suggest harmonious combinations or bold contrasts that enhance the vehicle’s overall look. This technology empowers you to create a truly personalized vehicle, where every detail aligns with your aesthetic vision. By leveraging these algorithms, automakers can offer more diverse and striking designs, transforming the way you experience vehicle customization. Additionally, integrating creative problem-solving techniques ensures that these designs meet both aesthetic and functional standards, leading to more innovative and user-centered outcomes.

Key Benefits of Algorithm-Driven Design in Cars

Algorithm-driven design opens new levels of innovation, allowing you to create more innovative and efficient car models. It also helps cut manufacturing costs by optimizing material use and streamlining production processes. Plus, this approach enhances vehicle performance, providing better safety, aerodynamics, and driving experience.

Enhanced Design Innovation

Enhanced design innovation in cars is transforming how vehicles meet both aesthetic and functional demands. You now have the opportunity to experience smarter, more adaptable vehicles shaped by advanced algorithms. These designs improve aerodynamics, optimize weight, and enhance safety features, all while supporting autonomous driving capabilities. The integration of algorithm-driven design also boosts vehicle cybersecurity by creating structures resistant to cyber threats. You benefit from a seamless blend of form and function, where aesthetics are not compromised for performance. Additionally, AI-driven predictive analytics can anticipate maintenance needs, reducing downtime and improving overall vehicle reliability. Cybersecurity is strengthened through innovative structural design that defends against emerging threats.

Reduced Manufacturing Costs

By streamlining the design process through advanced algorithms, manufacturers can substantially cut production costs. Algorithm-driven design enables more precise material usage, reducing waste and sourcing expenses. This process streamlining eliminates the need for multiple prototyping phases, saving both time and money. With generative design, you can optimize parts for manufacturing efficiency, resulting in fewer complex components and simplified assembly. These improvements lead to significant cost reduction across the production cycle. Additionally, algorithms help identify the most cost-effective manufacturing methods without sacrificing quality. As a result, you benefit from lower material costs, reduced labor, and minimized downtime. Moreover, AI-driven insights facilitate continuous improvements in manufacturing workflows, further enhancing cost savings. Overall, embracing algorithm-driven design translates into more affordable manufacturing, making vehicles more accessible while maintaining high standards of safety and innovation.

Improved Vehicle Performance

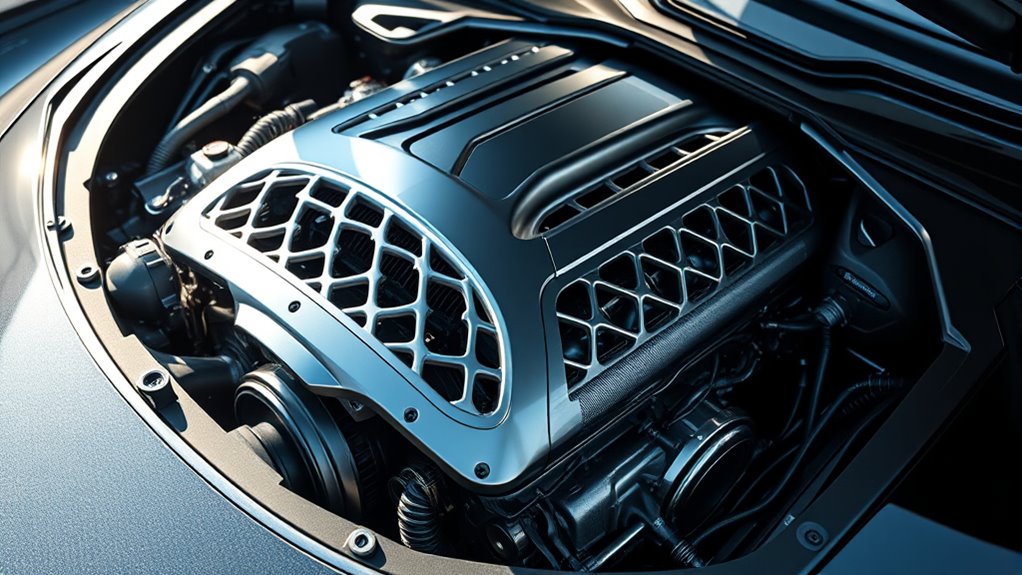

When advanced algorithms guide the design process, vehicles can achieve superior performance through optimized structures and systems. These innovations enhance driver safety and fuel efficiency by intelligently balancing weight, aerodynamics, and material strength. Algorithm-driven designs create lighter, more durable frames that improve handling and crash resilience. They also optimize airflow, reducing drag and increasing fuel economy. Additionally, these designs enable better placement of safety features, minimizing injury risk during collisions. You benefit from vehicles that respond more precisely to your driving style while consuming less fuel. The integration of algorithms ensures continuous performance improvements, adapting to new data and driving conditions. Incorporating mindfulness principles into design processes can further promote thoughtful innovation and user well-being. Overall, this approach results in cars that are safer, more efficient, and more responsive to your needs.

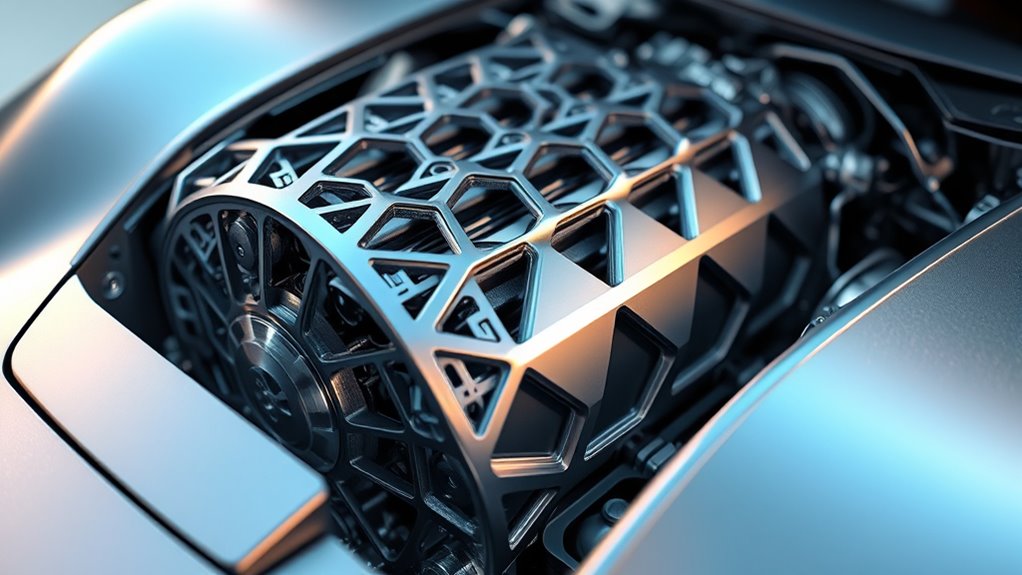

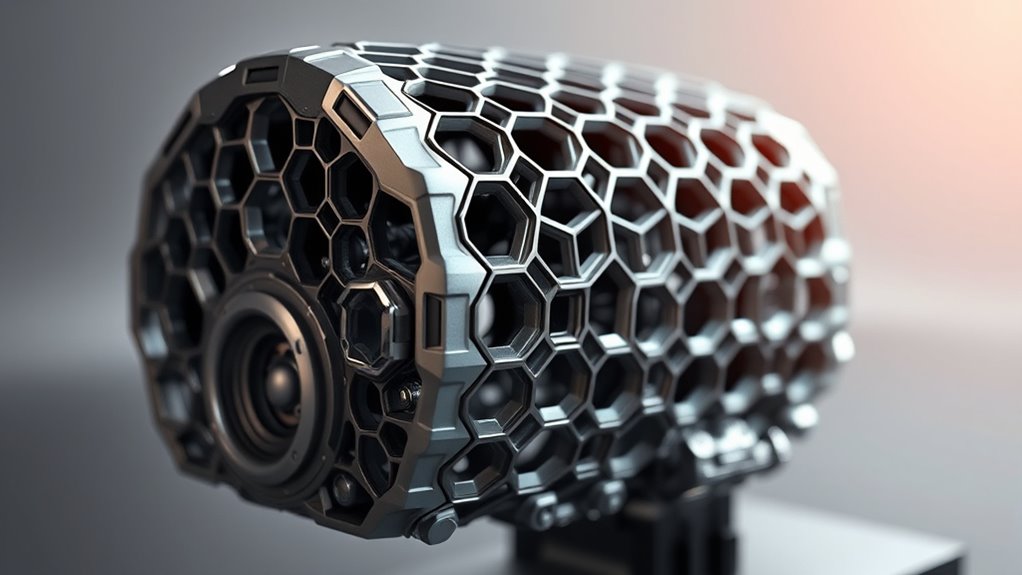

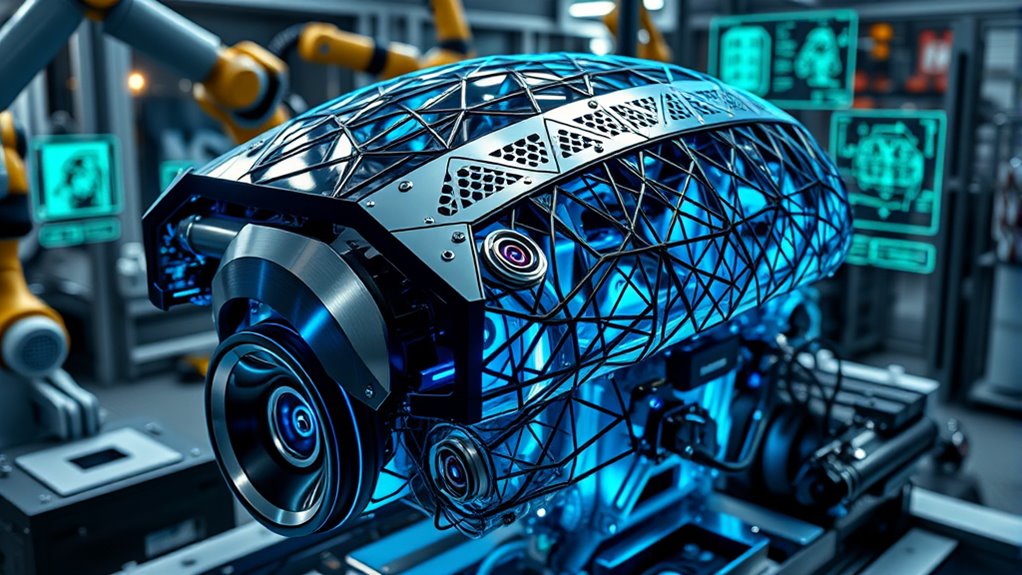

Materials and Structures Optimized by Generative Models

Generative models are revolutionizing how materials and structural components are designed for vehicles. By leveraging these models, you can achieve significant material innovation, discovering new composites or alloys that offer better strength-to-weight ratios. Structural optimization becomes more precise as algorithms explore countless configurations, identifying designs that traditional methods might overlook. These advanced techniques enable you to reduce weight without sacrificing safety or durability, enhancing overall vehicle efficiency. Generative models also facilitate the creation of complex geometries that optimize load distribution and resist stress, leading to more resilient structures. Incorporating material science innovations can further enhance design outcomes, allowing for even more tailored and high-performing vehicle parts. As a result, you gain the ability to develop lightweight, robust parts tailored specifically to your vehicle’s needs, pushing the boundaries of conventional design and access new possibilities in automotive engineering.

Case Studies: Innovative Vehicles Created With Generative Design

Innovative vehicles demonstrate the tangible benefits of generative design through real-world applications. These case studies showcase how algorithms optimize structures for performance, weight, and efficiency, especially in autonomous driving and electric propulsion. You’ll see how generative models create lightweight, aerodynamic frames that enhance energy efficiency while maintaining safety. For example, some electric vehicles feature complex, organic shapes that reduce drag and improve range. Others use generative design to develop battery enclosures that maximize space and cooling. These innovations demonstrate that algorithm-driven design accelerates development, reduces material waste, and results in smarter, more adaptable vehicles. By integrating generative principles, automakers push the boundaries of what’s possible in autonomous and electric vehicles, setting new standards in efficiency and innovation. Generative design also enables the customization of parts to better suit specific performance needs, further advancing automotive engineering.

The Role of Artificial Intelligence in Modern Automotive Engineering

Artificial intelligence has become a cornerstone of modern automotive engineering, driving advancements that enhance safety, efficiency, and user experience. You now rely on AI for autonomous driving systems that analyze sensor data, make real-time decisions, and improve navigation. AI also strengthens vehicle cybersecurity by detecting threats and preventing hacking attempts, safeguarding your data and safety. These technologies enable cars to adapt to changing conditions, optimize performance, and reduce accidents. As AI continues to evolve, you’ll see smarter features that anticipate your needs and respond swiftly. With AI integrated into every aspect, your vehicle becomes more intuitive, secure, and reliable, transforming the driving experience into a seamless, high-tech journey. Continuous monitoring of market conditions and portfolio performance is essential to stay ahead in the rapidly evolving automotive landscape.

Challenges and Limitations of Algorithmic Car Design

While algorithmic car design offers exciting possibilities, it also presents significant challenges that can’t be overlooked. One major issue is algorithmic bias, which can lead to designs that unintentionally favor certain features or overlook safety and accessibility concerns. Design unpredictability is another obstacle, as algorithms sometimes produce unexpected results that require manual refinement, slowing development. Additionally, these systems depend heavily on quality data; poor data can compromise design quality. Lastly, technical complexity can create barriers to implementation, demanding advanced expertise and resources. To succeed, you must understand these limitations, continuously refine algorithms, and ensure diverse, unbiased data. Recognizing these challenges helps you develop more reliable, innovative, and ethical algorithm-driven car designs.

Future Trends: The Integration of Generative Design and Sustainability

As the automotive industry embraces generative design to overcome some of its previous limitations, a strong focus is emerging on sustainability. You’ll see manufacturers prioritizing sustainable materials, such as recycled composites and bio-based plastics, to reduce environmental impact. Generative algorithms enable you to optimize designs that use less material while maintaining strength and safety. Eco-friendly manufacturing processes are also gaining traction, with additive manufacturing and energy-efficient techniques becoming standard. These innovations allow you to create vehicles that are lighter, more efficient, and environmentally conscious. By integrating generative design with sustainable materials and eco-friendly methods, you not only meet regulatory demands but also appeal to eco-aware consumers. This combination promises a future where innovation and sustainability go hand in hand, shaping greener, smarter vehicles.

Impact on Manufacturing Processes and Supply Chains

Generative design is transforming manufacturing processes and supply chains by enabling more flexible, efficient, and precise production methods. It reduces reliance on traditional supply chain models, helping you better navigate supply chain disruptions. Automation in manufacturing accelerates, allowing you to produce complex parts faster and with less waste. This shift streamlines logistics, minimizes inventory needs, and enhances responsiveness to market changes. You’ll see improved quality control through integrated digital workflows. Additionally, customizable designs can be quickly adapted, reducing lead times. The impact extends to sourcing, where more localized production becomes feasible. Overall, generative design enhances your ability to manage risks, optimize resources, and stay competitive amid evolving global supply chain challenges.

- Reduced supply chain disruptions and delays

- Increased manufacturing automation efficiency

- Faster, more adaptable production cycles

- Enhanced quality and customization options

Frequently Asked Questions

How Does Generative Design Influence Vehicle Safety Standards?

You see, vehicle safety standards get a boost through material optimization and crashworthiness analysis. When you use generative design, it helps identify the strongest yet lightest materials, improving crash resistance. By simulating impacts and stress points, the process guarantees your vehicle meets safety regulations. This innovative approach means safer cars for you, as engineers can craft designs that maximize strength without adding unnecessary weight.

Are Algorithmically Designed Cars More Cost-Effective to Produce?

You might think algorithmically designed cars are pricier, but surprisingly, they’re often more cost-effective to produce. Thanks to their precise, optimized parts, you get better manufacturing efficiency and significant cost reduction. By minimizing waste and streamlining assembly, these designs cut expenses. So, while it seems complex, the truth is, you could save money with cars engineered by algorithms—making innovation not just smarter but also more budget-friendly.

What Software Tools Are Most Commonly Used in Generative Automotive Design?

You’ll find that parametric modeling and topology optimization are the most common software tools in generative automotive design. These tools let you create complex, optimized structures by adjusting parameters and refining material layouts. Programs like Autodesk Fusion 360 and Altair Inspire enable you to explore innovative designs efficiently. By using these tools, you can enhance performance, reduce weight, and accelerate development, making your design process more innovative and cost-effective.

How Do Consumer Preferences Impact Generative Design Processes?

Imagine walking into a showroom where your preferences shape every curve and color, creating a truly personalized experience. Consumer preferences directly influence generative design processes, guiding algorithms to craft vehicles that reflect individual tastes. This fosters aesthetic innovation and personalized customization, ensuring each car resonates with the owner’s unique style. By listening to what customers want, automakers can produce innovative designs that blend functionality with personal expression, making every drive a reflection of the driver’s identity.

Can Generative Algorithms Adapt to Emerging Automotive Regulations?

You wonder if generative algorithms can modify to emerging automotive regulations. With their inherent algorithm flexibility, they can quickly incorporate new rules into their design parameters. This regulation adaptation allows you to ensure that your vehicle designs remain compliant as policies evolve. By continuously updating the algorithms with latest regulatory data, you can streamline compliance processes and stay ahead in the competitive automotive industry.

Conclusion

As you embrace the future of car design, remember that generative algorithms are your compass, guiding innovation through uncharted territory. They’re transforming ideas into reality faster than ever, like a symphony of creativity and technology working in harmony. With endless possibilities on the horizon, you’ll find yourself at the forefront of a revolution where imagination drives progress, and each new vehicle is a masterpiece born from the dance of algorithms and engineering excellence.